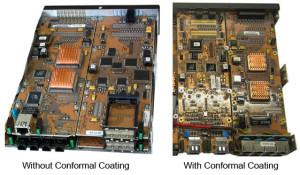

Understanding the Importance of Silicone Conformal Coating

A variety of silicone conformal coating options is available. The different chemical properties exhibited by these materials can meet diverse industry demands. However, the material used ultimately depends on the application requirements.

When to Use Silicone Conformal Coating

Silicone conformal coating can be a wise option in the following instances:

1. High Temperature Applications

Silicone conformal coating can be used in applications with continuous operating temperatures of 200 ºC. Compared to urethane, which can be operated at temperatures of 125 ºC, silicone is the better choice. Special silicone materials with a maximum temperature rating of 600 ºC can be used in high temperature applications.

2. Moisture-rich Environments/ Applications

Silicone conformal coating serves as an excellent moisture barrier. A thick layer of silicone can make the entire application moisture resistant. It offers the highest degree of moisture protection compared to other conformal coating materials.

3. Quickturn Orders

Silicone conformal coating takes approximately one hour to cure at room temperature. This can prove useful for orders that need to be processed quickly.

When Not to Use Silicone Conformal Coating

The thickness of silicone conformal coating ranges between 0.00197″and 0.00827″. This measurement is much thicker than that applied when using other materials. This can prove to be difficult to work with when:

1. The PCB and application has tight clearance tolerances.

2. The solder joints are not strong enough to support stress associated with thick PCB conformal coating layers.

Hence, silicone conformal coating has various advantages and limitations, as do all materials. The conformal coating material should be chosen in accordance with the application with which it will be integrated.